Bambu Lab X1E for Manufacturing: Why Factories Are Choosing This 3D Printer for Production

The Bambu Lab X1E isn’t just another desktop 3D printer — it’s a serious production tool designed for manufacturing environments. While most 3D printers target hobbyists and prototyping, the X1E was built from the ground up for enterprise and factory use, with features like an enclosed chamber, industrial-grade materials support, and network security that traditional consumer printers simply can’t match.

In this article, we explore why manufacturing companies are increasingly adopting the Bambu Lab X1E, what makes it different from consumer-grade printers, and how it addresses critical concerns around security, material compatibility, and production reliability.

What Is the Bambu Lab X1E?

The Bambu Lab X1E is an enterprise-focused CoreXY 3D printer released in 2024. It builds on the foundation of the popular X1-Carbon but adds several critical features for professional and industrial environments:

- Fully enclosed heated chamber — Reaches up to 60°C for printing engineering-grade materials like ABS, ASA, PA (Nylon), PC (Polycarbonate), and carbon fiber composites

- Active chamber heating — Unlike passive enclosures, the X1E actively controls chamber temperature for consistent results across long prints

- Enterprise network security — LAN-only mode, no mandatory cloud connectivity, compatible with corporate network policies

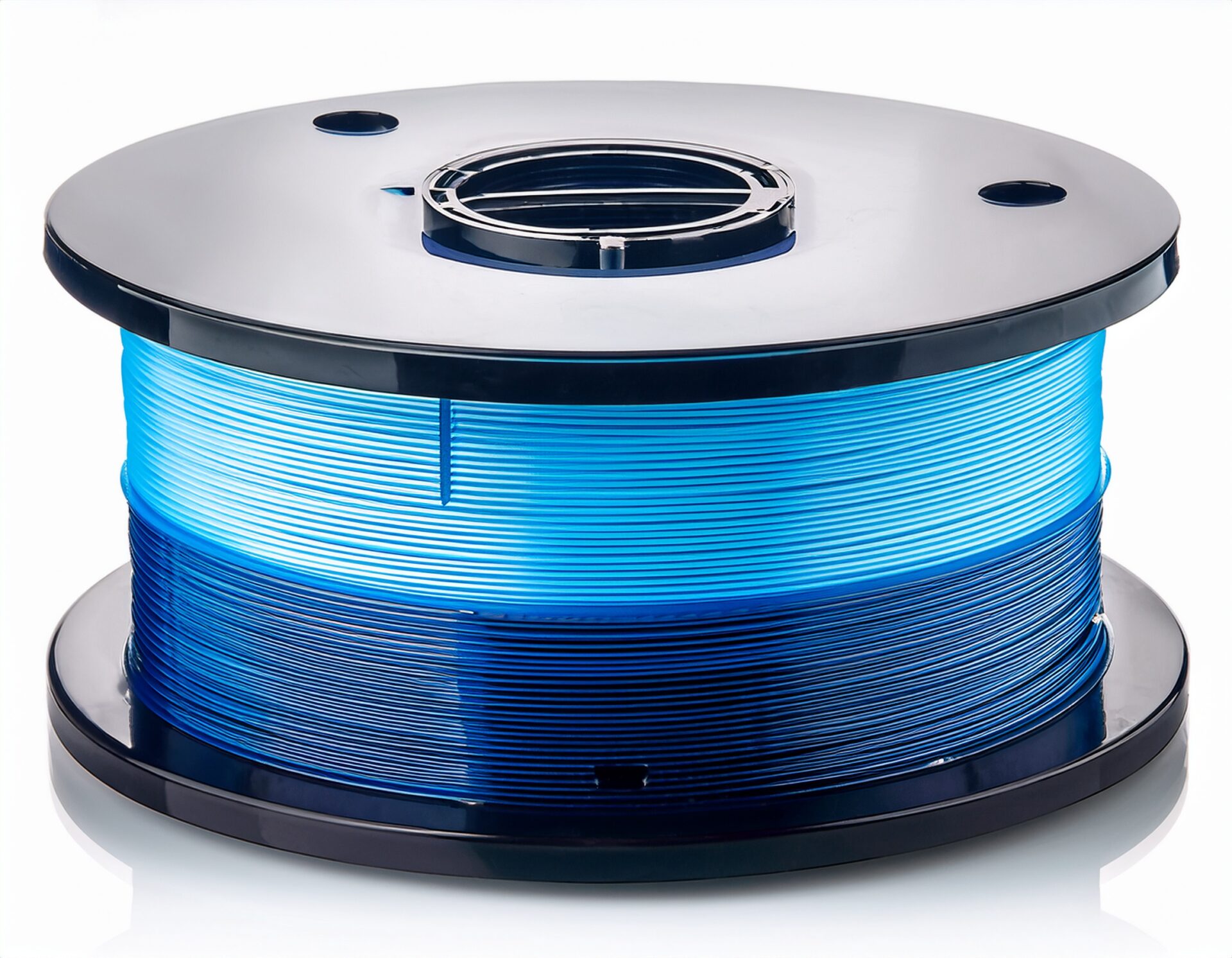

- Multi-material system (AMS) — Supports up to 4 materials in a single print via the Automatic Material System

- HEPA + activated carbon filtration — Essential for printing ABS, ASA, and other materials that emit VOCs and ultrafine particles

- Hardened steel nozzle — Standard equipment for abrasive materials like carbon fiber and glass fiber reinforced filaments

The Enterprise Security Blind Spot in 3D Printing

One of the most overlooked aspects of deploying 3D printers in manufacturing is network security. Most consumer and prosumer 3D printers require cloud connectivity to function — they send print data to external servers, require user accounts, and often have limited control over data flow.

For manufacturing companies, this creates serious security concerns:

- Intellectual property exposure — CAD files and print data passing through cloud servers could be intercepted or stored

- Network vulnerability — Cloud-connected devices on factory networks create potential attack vectors

- Compliance requirements — Industries like defense, aerospace, and medical devices have strict data handling requirements (ITAR, CMMC, ISO 27001)

- Supply chain risk — Dependency on third-party cloud services means a server outage could halt production

How the X1E Addresses Security

The Bambu Lab X1E was specifically designed with enterprise IT requirements in mind:

- LAN-only mode — The printer can operate entirely on a local network without any internet connectivity. All communication stays within your firewall.

- No mandatory cloud account — Unlike many competitors, the X1E can be set up and operated without creating a Bambu Lab cloud account.

- Local slicer processing — Bambu Studio (the companion slicer software) processes files locally on the user’s computer, not in the cloud.

- Encrypted communication — Print data transmitted over the local network is encrypted.

- Firmware control — IT teams can manage firmware updates on their own schedule rather than being forced to accept automatic updates.

Engineering Materials: Beyond PLA

The real advantage of the X1E for manufacturing is its ability to reliably print engineering-grade materials that consumer printers struggle with. The active chamber heating is the key differentiator here.

Materials the X1E Handles Well

| Material | Key Properties | Common Applications |

|---|---|---|

| PA6-CF (Nylon Carbon Fiber) | High strength, stiffness, heat resistance | Jigs, fixtures, structural parts |

| PC (Polycarbonate) | Impact resistance, optical clarity, heat resistance | Protective covers, housings, lenses |

| ABS | Good balance of strength and flexibility | Functional prototypes, enclosures |

| ASA | UV resistance, weather resistance | Outdoor parts, automotive components |

| PA12-CF | Chemical resistance, low moisture absorption | End-use parts, chemical environments |

| PPA-CF (High-temp Nylon) | Extreme heat resistance (up to 170°C HDT) | Under-hood automotive, high-temp tooling |

| TPU | Flexibility, impact absorption | Gaskets, seals, vibration dampeners |

Why Chamber Heating Matters

Engineering plastics like Nylon, PC, and ABS are prone to warping, cracking, and delamination when printed in an uncontrolled environment. The rapid cooling of deposited layers creates internal stresses that cause parts to warp or crack — especially on larger prints.

The X1E’s active chamber heating maintains a consistent ambient temperature around the part during printing. This dramatically reduces:

- Warping — Even large ABS and Nylon parts print flat without lifting from the bed

- Layer delamination — Consistent temperature means better interlayer bonding throughout the print

- Internal stress — Parts have fewer residual stresses, resulting in better dimensional accuracy and mechanical performance

- Print failure rate — Significantly fewer failed prints compared to open-frame or passively enclosed printers

Real-World Manufacturing Use Cases

1. Production Jigs and Fixtures

Perhaps the most common enterprise application. Manufacturing lines need custom jigs, fixtures, and assembly aids that are specific to each product. Traditional manufacturing (CNC machining, injection molding) of these tools is expensive and slow. With the X1E, a factory can design and print a custom fixture in hours rather than weeks, using PA6-CF or PC for the required strength and durability.

2. Low-Volume End-Use Parts

For production runs under 500-1000 units, 3D printing can be more cost-effective than injection molding (which requires expensive tooling). The X1E’s material compatibility means these parts can meet real-world performance requirements — not just serve as visual prototypes.

3. Rapid Prototyping with Production Materials

Testing a prototype made from PLA tells you very little about how the final part (made from PA or PC) will perform. The X1E allows engineers to prototype in the actual production material, giving meaningful mechanical and thermal test results before committing to mass production tooling.

4. Spare Parts On-Demand

Manufacturing facilities with aging equipment often struggle with obsolete spare parts. Rather than maintaining expensive parts inventories or waiting weeks for custom machined replacements, the X1E enables on-demand production of replacement parts in engineering-grade materials.

X1E vs. Industrial 3D Printers

How does the X1E compare to dedicated industrial 3D printers from companies like Stratasys, Markforged, or Ultimaker?

| Feature | Bambu Lab X1E | Industrial FDM Printers |

|---|---|---|

| Price | ~$2,500 | $15,000–$100,000+ |

| Build Volume | 256 x 256 x 256mm | Varies (often larger) |

| Chamber Heating | Up to 60°C (active) | Up to 70–120°C |

| Material Range | Excellent (PA, PC, ABS, CF composites) | Excellent to Specialized |

| Print Speed | Very fast (CoreXY, up to 500mm/s) | Moderate (typically 50–150mm/s) |

| Multi-material | Yes (AMS, 4 materials) | Limited (usually dual) |

| Network Security | LAN-only mode available | Varies by vendor |

| Service/Support | Community + Bambu support | Dedicated enterprise support |

| Certification | CE, FCC | Often UL, CE, additional certs |

The X1E’s main advantage is its price-to-performance ratio. At roughly $2,500, you can deploy multiple X1E units for the cost of a single industrial printer. This distributed approach offers redundancy (if one printer goes down, production continues on others) and flexibility (each printer can run different parts simultaneously).

Setting Up the X1E for Enterprise Deployment

Network Configuration

- Connect the X1E to your corporate LAN via Ethernet (recommended) or Wi-Fi

- Enable LAN-only mode in the printer settings to disable cloud connectivity

- Configure static IP addresses for each printer for reliable network management

- Set up Bambu Studio on workstations to communicate with printers via LAN discovery

- Block outbound internet access for printer IPs at the firewall level for additional security

Air Quality Management

When printing ABS, ASA, and other materials that emit VOCs and ultrafine particles, proper ventilation is critical — especially in enclosed factory environments. The X1E includes built-in HEPA and activated carbon filtration, but for continuous production, additional measures are recommended:

- Connect the X1E’s exhaust port to an external ventilation system

- Monitor VOC levels in the printing area with dedicated sensors

- Replace HEPA and carbon filters according to the maintenance schedule (or more frequently with heavy use)

- Ensure the room has adequate general ventilation (minimum 6 air changes per hour recommended)

Limitations to Consider

The X1E is impressive for its price point, but it’s important to understand its limitations in an enterprise context:

- Build volume — At 256mm cubed, large parts may need to be split and assembled. Industrial printers offer larger build volumes.

- Chamber temperature — 60°C is sufficient for most engineering plastics but falls short of the 70-120°C needed for high-performance polymers like PEEK or PEI.

- Certification — The X1E has CE and FCC but may lack specific industry certifications (UL, medical device standards) required in some environments.

- Support — Bambu Lab offers good consumer support, but enterprise SLAs and on-site service are not at the level of Stratasys or similar vendors.

- Long-term track record — Bambu Lab is a relatively young company. Some enterprises may hesitate to depend on a manufacturer with limited operational history.

Conclusion: The Right Tool for the Right Job

The Bambu Lab X1E represents a paradigm shift in accessible manufacturing-grade 3D printing. It doesn’t replace dedicated industrial systems for high-volume or exotic-material applications, but it fills a critical gap: affordable, reliable, secure 3D printing for everyday manufacturing needs.

For factories looking to start or expand their 3D printing capabilities — especially for jigs, fixtures, prototyping, and low-volume production — the X1E offers an unbeatable combination of material versatility, print quality, speed, and enterprise-ready security at a fraction of the cost of traditional industrial solutions.

The question isn’t whether manufacturing companies will adopt desktop 3D printing — it’s how quickly. And the X1E is making that transition easier than ever.